Menu

-

-

F.A.Q

- How to identify genuine agarwood chip, natural or cultivated

- How to identify oil injection / absorption fake agarwood beads

- How to know if there are more than one oil in your oil

- How to make your wood bracelet or mala darker

- How to tell if an Agarwood bead sinks WITHOUT sinking it under water?

- How does back flow incense work and how do you burn it?

- Where to start if you don't know what agarwood is ?

- Why are you losing money if you buy seeds and plants?

- Which agarwood incense should I choose?

- Frequently Asked Questions

- Agarwood Related Articles

- Shipping

-

SHOP - Agarwood

-

SHOP - Other Fragrant Wood

-

SHOP - Incense Holder and Burner

-

- FREE Oud Oil guide

- Testimonials

- "Why did you buy this?"

- Contact us

- About Us

- +61430284329

- Login

-

English

Agarwood essential oil production with diagram

December 01, 2025 4 min read

Hydrodistillation vs. Steam Distillation: Which is Better for Agarwood Oil?

Both hydrodistillation and steam distillation are traditional methods for extracting essential oils from plant materials, but they differ in how the plant interacts with water and steam during the process. Here is a clear comparison of the two:

What is Steam Distillation?

In steam distillation, steam is generated in a separate boiler and then passed through the plant material contained in another chamber. The steam’s heat vaporises the volatile compounds without direct contact between the plant and boiling water. The vapours are then condensed and collected, separating into oil and hydrosol.

Key characteristics:

- The plant material is not submerged in water; only steam passes through it.

- The temperature can be controlled more precisely, reducing the risk of damaging sensitive compounds.

- This method is more suitable for delicate flowers and leaves, such as lavender, rose, and eucalyptus.

- It is faster and more efficient, often producing cleaner oils with lighter aroma notes.

What is Hydrodistillation?

In hydrodistillation, the plant material is submerged directly in water, and the entire mixture is heated. As the water boils, steam carrying volatile aromatic compounds is produced. This steam then passes through a condenser, where it cools and separates into two layers: essential oil (which floats or sinks depending on density) and water (known as hydrosol).

Key characteristics:

- The plant material is in direct contact with boiling water.

- This method is suitable for heavier plant materials (such as woods, roots, or resins) that can withstand direct boiling.

- The process can take longer because water must heat the plant material thoroughly.

- There is a risk of hydrolysis (chemical breakdown) of delicate components, as some compounds can react with water when exposed for long periods.

- It is often used in the traditional extraction of oils such as agarwood, sandalwood, and vetiver.

At a Glance: Hydrodistillation vs. Steam Distillation

| Aspect | Hydrodistillation | Steam Distillation |

|---|---|---|

| Contact with water | Plant material submerged in water | Steam passes through plant material |

| Risk of hydrolysis | Higher | Lower |

| Suitable materials | Woods, roots, resins | Flowers, leaves, herbs |

| Process control | Harder to control the temperature | Easier to control the temperature |

| Oil quality | May be darker or heavier | Usually lighter |

In short, hydrodistillation is an older, simpler technique ideal for dense materials that can tolerate boiling, while steam distillation is more refined, efficient, and suited for temperature-sensitive botanicals.

The Verdict for Agarwood (Oud): Why Hydrodistillation Could Be Better

For agarwood, hydrodistillation is generally considered the better method, although both hydrodistillation and steam distillation can technically be used. The preference for hydrodistillation comes from how agarwood’s unique chemical and physical properties respond to heat, water, and fermentation.

Here is a detailed explanation:

1. The Unique Nature of Agarwood Resin

Agarwood (Aquilaria spp.) is a dense, resinous wood formed as a result of fungal or microbial infection. The resin contains a complex mixture of compounds, including sesquiterpenes (such as agarospirol, β-spathulenol, and 7-epi-γ-eudesmol) and chromones, many of which are less volatile and heavier than the compounds found in lighter flowers or herbs.

These heavier molecules require longer heating and direct contact with water to be released effectively, which hydrodistillation provides.

2. The Hydrodistillation Advantage for Oud

In hydrodistillation, the agarwood powder or small chips are immersed in water and boiled for several days. This direct contact with water:

- Softens the wood fibres, allowing the trapped resinous compounds to be released.

- Facilitates a mild hydrolytic reaction, which can alter some compounds slightly, deepening the oil’s aroma profile.

- Enables the formation of heavier, more complex aromatic notes that are characteristic of traditional agarwood oil, including earthy, woody, and animalic tones.

Traditional producers in regions such as Cambodia, Vietnam, and India have long relied on hydrodistillation precisely because it yields these deep, full-bodied oils that mature beautifully over time.

3. The Limitations of Steam Distillation for Agarwood

Steam distillation is cleaner and faster, but it is less suitable for agarwood because:

- The steam passes through the wood without fully soaking it, so resin trapped deep inside the wood may not release completely.

- The process often yields a lighter oil with a weaker base note, lacking the richness prized in fine oud oils.

- Since agarwood oil components are not highly volatile, steam alone is insufficient to extract the full range of compounds effectively.

4. Why Hydrodistillation Produces Superior Oud Oil most of the time?

- Produces a richer, more complete aroma profile with both high and low notes.

- Extracts more oil from the same amount of material due to longer exposure to heat and water.

- The prolonged process allows natural fermentation residues in soaked agarwood powder to contribute to the oil’s unique barnyard or animalic depth, often valued in traditional oud profiles.

- The resulting oil ages better, developing smoother and more complex tones over time.

5. When Could Steam Distillation Be A Better Option?

Hydrodistillation often involves soaked and fermented agarwood, which produces deep, barnyard tones. Some producers or perfumers might prefer a non-fermented, cleaner profile, where the natural woody or medicinal character of the wood dominates. Steam distillation, when done cleanly, can achieve this.

Also, the key is the temperature control and pressure. I saw some of Oud oil produced by the steam distillation below the boiling point, low pressure, with longer simmering time. These oil will produce fresher top notes, clean, bright, medium woodiness.

When distilling in high temperatures and high pressure, the oil will have burn notes, and less complexity.

When doing right, they could be very beautiful oil too. With the right equipment and right skill, we can produce high-quality steam-distilled oud oil .

6. Summary: Hydro vs. Steam for Agarwood

| Aspect | Hydrodistillation | Steam Distillation |

|---|---|---|

| Extraction efficiency for agarwood | High | Moderate |

| Aroma quality | Deep, complex, long-lasting | Lighter, cleaner but less character |

| Yield | Higher | Lower |

| Traditional use | Widely used in oud oil production | Rarely used for oud |

| Suitable for | Resinous woods | Flowers and herbs |

Final words

Hydrodistillation is the preferred and traditional method for agarwood because it extracts a broader range of aromatic compounds, enhancing the oil’s complexity and depth. Steam distillation, while cleaner, does not capture the rich, aged essence that defines authentic agarwood oil.

It all depends on the end users, scent is subjective so whatever users want, distillers will accomodate.

Leave a comment

Comments will be approved before showing up.

Also in News

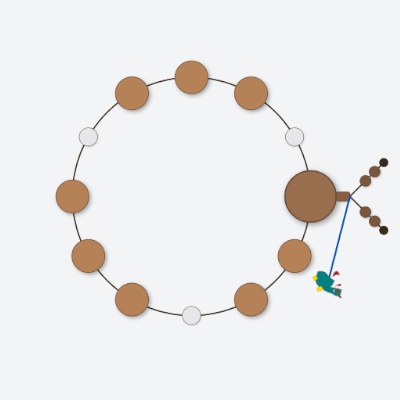

What is Tasbih? The Deep Meaning of Subhan Allah and the Role of Prayer Beads

November 09, 2025 4 min read